UK Perforation has its new dedicated Perforation facility for 2020!

COVID-19.

We are still operating a reduced service throughout the period.

If sending us materials, please see our contact page for updated delivery address details. Thank you.

We are still operating a reduced service throughout the period.

If sending us materials, please see our contact page for updated delivery address details. Thank you.

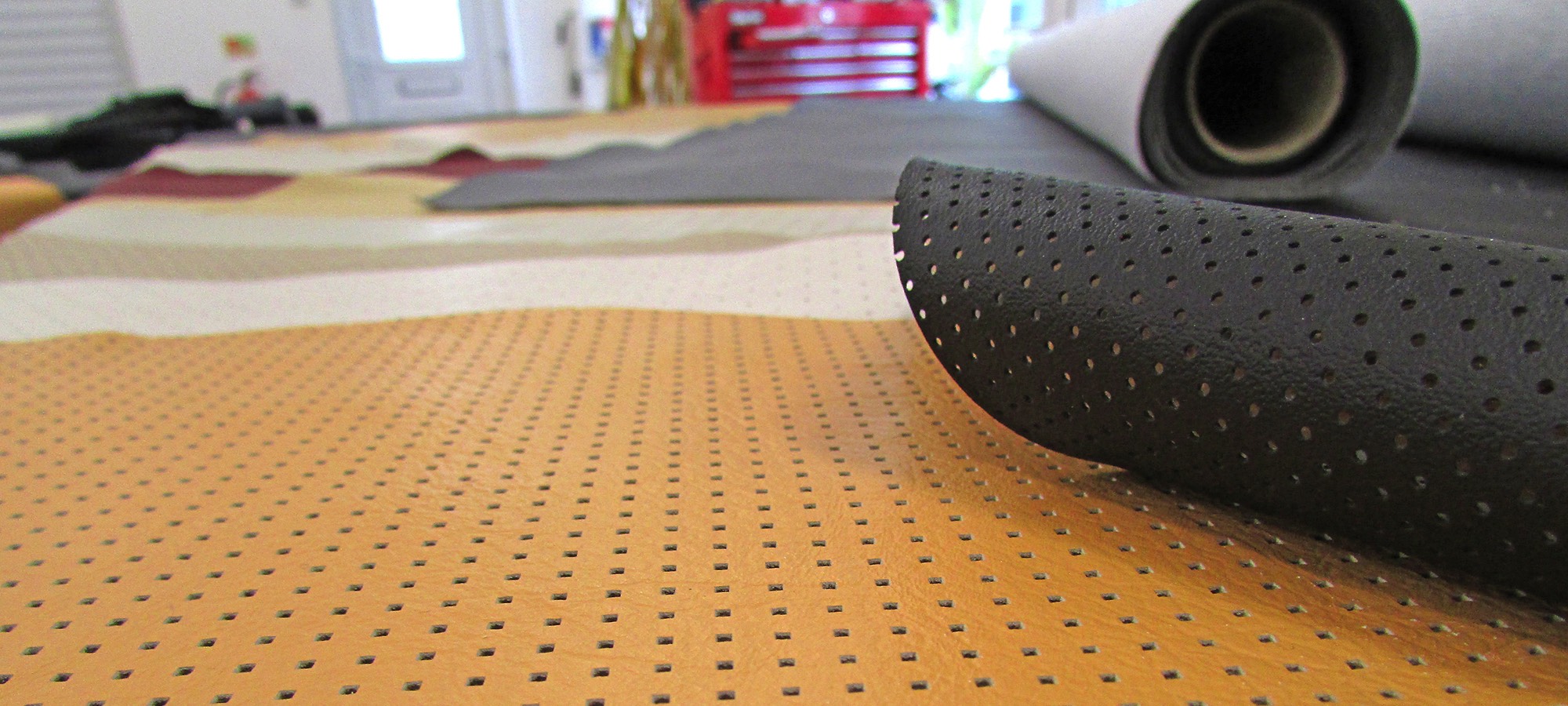

Perforating and embossing leather, vinyl and roll materials for top product manufacturers worldwide, is our speciality! We produce in our UK workshops and ship globally, on a daily basis.

Located and processing materials in the UK for a surprisingly wide range of markets, we have tooling to allow us to produce the popular holes and standard perforation patterns and embossing patterns used in a wide range of industries, for example: Automotive, Aviation, Marine, Fashion, Design, Filtration, Flotation, Packaging, Food and Drink, Advertisement and more.

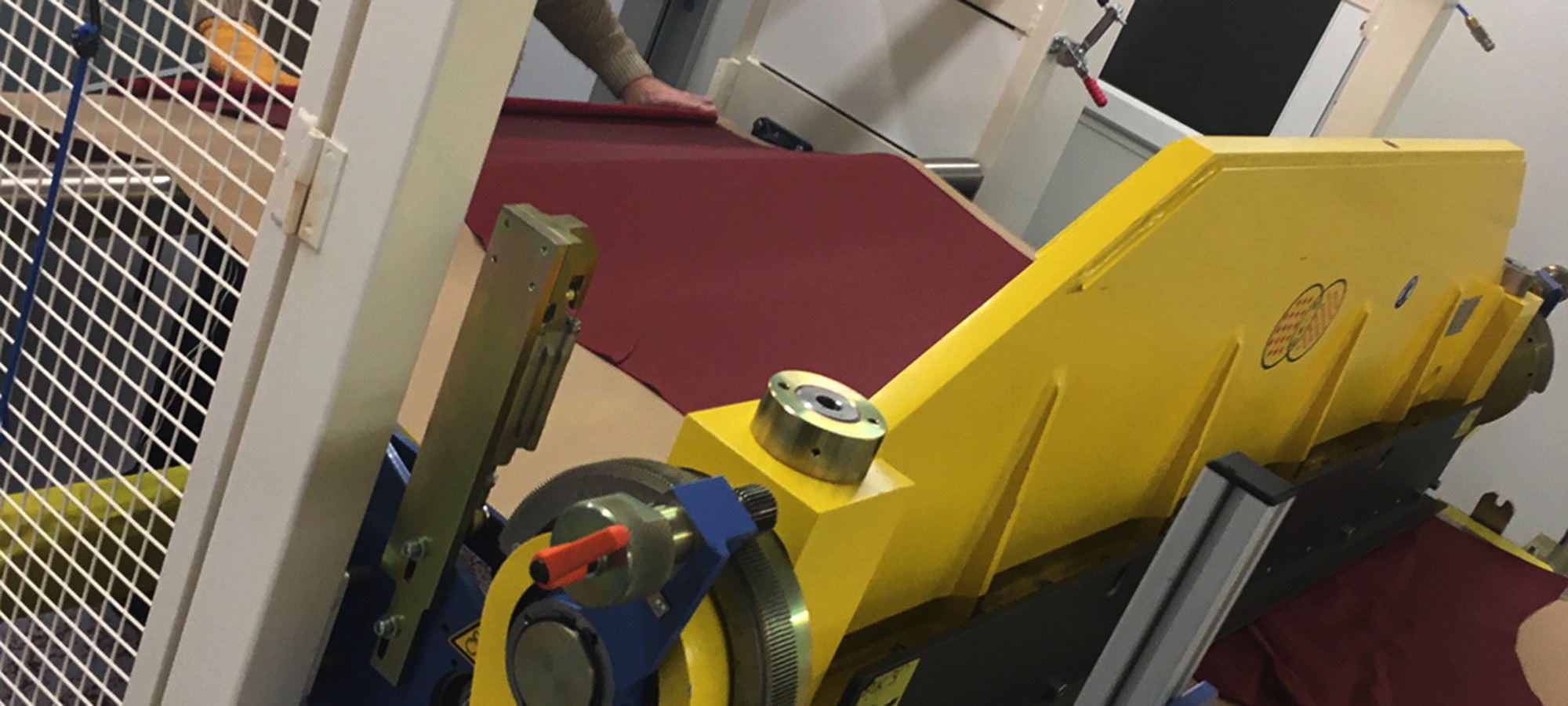

Our contract perforation departments have the latest technology and machinery for both the perforation and embossing of materials, using machinery made with decades of experience from our German machine supplier.

- 3 separate dedicated perforation booths

- Clean Room processing for food packaging products

- Specialist multi-layer processing for large production runs

- Increased capabilities to accommodate larger batch productions

Located and processing materials in the UK for a surprisingly wide range of markets, we have tooling to allow us to produce the popular holes and standard perforation patterns and embossing patterns used in a wide range of industries, for example: Automotive, Aviation, Marine, Fashion, Design, Filtration, Flotation, Packaging, Food and Drink, Advertisement and more.

Our contract perforation departments have the latest technology and machinery for both the perforation and embossing of materials, using machinery made with decades of experience from our German machine supplier.

Just talk to us about your specific needs and we'll be delighted to endeavour to meet them.

With a tailored choice of production methods available including our:

'Clean room facility' this perforation facility is fitted with hygienic wipeable surfaces, H1 food spec' machine lubricants, climate controlled, air filtration and dust extraction - allowing us to process packaging materials for the food industry and other sensitive applications.

'Multi layer' / 'Multi roll' processing on some thinner materials is possible and can be more cost-effective for larger volume production.

Our bespoke built Re-Roller machines have differential shafts allowing us to perforate more than one roll per shaft and process up to three layers at one time!

'Pre-cut shapes' We offer continuous perforation on a paper conveyor belt. This perforation method allows us to process small or large pre-cut shapes, up to 1600mm wide.

Our state-of-the-art perforation tooling uses the 'Patrix-matrix system' with tempered pins and cutting plates according to the scissor type principle, which results in the highest quality perforation available.

This type of tooling requires regular sharpening and maintenance to keep the quality of the service we offer. All maintenance and sharpening is carried out in-house at our workshops in the UK.

'Clean room facility' this perforation facility is fitted with hygienic wipeable surfaces, H1 food spec' machine lubricants, climate controlled, air filtration and dust extraction - allowing us to process packaging materials for the food industry and other sensitive applications.

'Multi layer' / 'Multi roll' processing on some thinner materials is possible and can be more cost-effective for larger volume production.

Our bespoke built Re-Roller machines have differential shafts allowing us to perforate more than one roll per shaft and process up to three layers at one time!

'Pre-cut shapes' We offer continuous perforation on a paper conveyor belt. This perforation method allows us to process small or large pre-cut shapes, up to 1600mm wide.

Our state-of-the-art perforation tooling uses the 'Patrix-matrix system' with tempered pins and cutting plates according to the scissor type principle, which results in the highest quality perforation available.

This type of tooling requires regular sharpening and maintenance to keep the quality of the service we offer. All maintenance and sharpening is carried out in-house at our workshops in the UK.

Tel: 01202 744366 or Email: enquiries@ukperforation.co.uk

version 15